Revolutionizing Manufacturing: The Future of Robotic Welding in Industry 4.0

As industries transition into Industry 4.0, robotic welding is emerging as a pivotal technology that is transforming manufacturing processes. According to a report by MarketsandMarkets, the global robotic welding market is expected to grow from $4.8 billion in 2021 to $11.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 19.2%. This growth is driven by the increasing demand for automated solutions that enhance precision, reduce labor costs, and improve safety in manufacturing environments. The integration of advanced technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) with robotic welding systems is setting new standards in operational efficiency and product quality. As companies strive for greater competitiveness and sustainability, adopting robotic welding not only streamlines production but also aligns with the digital transformation goals set forth in Industry 4.0.

The Impact of Industry 4.0 on Robotic Welding Efficiency and Productivity

The integration of Industry 4.0 technologies into robotic welding processes is transforming manufacturing efficiency and productivity. According to a report by the International Federation of Robotics (IFR), the global industrial robot market is expected to grow by 12% annually, reaching over $41 billion by 2024. This surge is fueled by advancements in IoT, AI, and machine learning, which allow for real-time data exchange and analytics, optimizing welding operations. Enhanced connectivity enables predictive maintenance, reducing downtime by approximately 30%, which significantly boosts overall productivity.

Tips: To maximize robotic welding efficiency, manufacturers should invest in training their personnel on smart technologies and automation tools. Additionally, incorporating real-time monitoring systems can help quickly identify and rectify issues, further enhancing workflow.

Moreover, studies indicate that implementing Industry 4.0 solutions can increase production rates by 20-60% while improving quality and consistency in welded products. By utilizing interconnected robotic systems that adapt to changing conditions and processes, companies can achieve a higher level of flexibility and responsiveness in their operations.

Tips: Regularly assess and update the software and firmware of your robotic systems to ensure they leverage the latest enhancements, leading to optimal performance and innovation in production processes.

Key Technologies Driving the Adoption of Robotic Welding Solutions

The landscape of robotic welding is rapidly evolving in Industry 4.0, driven by advancements in automation and smart technologies. The market for industrial welding robots is witnessing significant growth, with notable contributions from various segments such as spot welding robots, arc welding robots, and laser welding robots. Each of these types has unique applications across different sectors, including automotive and transportation, electronics, aerospace and defense, as well as metal and machinery industries. By integrating robotics into these processes, companies not only enhance precision but also improve efficiency and reduce operational costs.

Tips: When considering the adoption of robotic welding, businesses should evaluate their specific needs and the types of welding required in their operations. It's essential to invest in training for staff to ensure they can effectively manage and maintain these advanced systems, maximizing the potential benefits of robotic solutions.

The growth of this market is further fueled by the increasing demand for high-quality manufacturing with reduced turnaround times. As industries strive for greater productivity, the implementation of robotic welding solutions becomes critical, providing a competitive edge. Companies deploying these technologies can expect to see a boost in output quality, consistency, and safety in their manufacturing processes.

Tips: To stay ahead in this competitive landscape, companies should remain informed about emerging technologies and best practices in robotic welding, ensuring they harness the full potential of Industry 4.0 innovations.

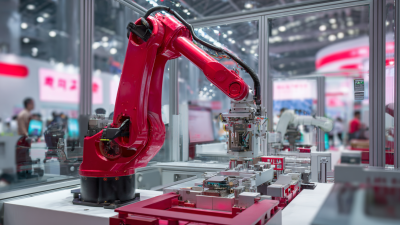

Analyzing Cost Savings and Return on Investment in Robotic Welding Implementations

The adoption of robotic welding systems is becoming increasingly prevalent in the context of Industry 4.0, driven by the quest for efficiency and precision. One of the most compelling reasons for businesses to invest in robotic welding is the significant cost savings it offers. With the ability to perform consistent, high-quality welds at a faster pace than human welders, robotic systems reduce labor costs and minimize material waste, leading to overall operational savings. By automating welding processes, companies can also avoid the costs associated with human error, further enhancing profitability.

Analyzing the return on investment (ROI) in robotic welding implementations reveals that while the initial setup costs can be substantial, the long-term benefits often outweigh these expenses. Businesses can expect a quick payback period due to increased production rates and reduced downtime. Additionally, robotic systems can operate continuously, allowing for extended production hours without fatigue-related issues. As the technology evolves, handling complex tasks with greater adaptability becomes feasible, making robotic welding not only a cost-effective solution but a strategic imperative for manufacturers aiming to stay competitive in an increasingly automated landscape.

The Role of Artificial Intelligence in Enhancing Robotic Welding Capabilities

Artificial Intelligence (AI) is poised to revolutionize robotic welding, marking a significant leap in Industry 4.0 manufacturing processes. By integrating AI algorithms with robotic systems, manufacturers can achieve enhanced precision and efficiency in welding operations. AI allows robots to learn from previous welding tasks, enabling real-time adjustments based on varying materials and environmental conditions. This adaptability not only improves the quality of welds but also reduces material waste and downtime, leading to more sustainable manufacturing practices.

Moreover, AI-driven analytics provide critical insights into the welding process, allowing for predictive maintenance and reducing the likelihood of equipment failure. As robots become smarter, they can anticipate issues before they arise, minimizing disruptions in production lines. The combination of AI and robotic welding also supports greater customization, enabling manufacturers to produce complex components that meet specific customer requirements without a significant increase in operational costs. This synergy not only enhances productivity but also positions companies to respond quickly to market changes, ensuring competitiveness in a fast-evolving industrial landscape.

Future Trends in Robotic Welding with AI Integration

This chart illustrates the projected increase in efficiency, accuracy, and cost savings in robotic welding with the integration of artificial intelligence over the coming years.

Future Trends: Predictive Maintenance and Smart Automation in Robotic Welding

Predictive maintenance and smart automation are at the forefront of transforming robotic welding within the framework of Industry 4.0. By leveraging artificial intelligence, manufacturers can proactively monitor equipment performance through sophisticated sensor data analysis. This capability allows for the anticipation of potential failures before they occur, significantly reducing downtime and maintenance costs. As the global demand for welding consumables is projected to rise from $13.4 billion in 2024 to $19.95 billion by 2032, the integration of predictive maintenance in the welding process becomes increasingly crucial for maintaining competitiveness.

Additionally, smart automation plays a vital role in enhancing the welding process's efficiency and precision. By employing advanced robotics equipped with machine vision systems, manufacturers can achieve remarkable levels of accuracy and consistency in their welding operations. The estimated CAGR of 5.3% in the welding consumables market highlights the industry's shift towards automation and AI-driven solutions. As these technologies continue to evolve, they promise to reshape the manufacturing landscape, enabling companies to maximize productivity and minimize waste through intelligent processes.

Related Posts

-

Digital Tips for Harnessing the Power of Robotic Automation Solutions

-

Exploring Industrial Robot Innovations at the 2025 China Import and Export Fair

-

Unlocking the Future of Robotic Welding Training at the 138th Canton Fair in China 2025

-

Exploring Industrial Automation Solutions at the 138th Canton Fair China 2025 Industry Insights

-

Exploring the Future of Robotic Manufacturing at China's 138th Canton Fair 2025

-

Unlocking the Future of Innovation through Robotic Programming for Beginners