How to Optimize Robotic Welding Cells for Maximum Efficiency?

The integration of robotic welding cells in manufacturing has significantly transformed the industry. According to a report by the International Federation of Robotics, the global market for industrial robots is expected to reach $23 billion by 2028. Robotic welding cells enhance productivity, reduce labor costs, and ensure consistent quality.

Dr. Emily Carter, an expert in automation engineering, once stated, "Optimizing robotic welding cells is crucial for staying competitive." This highlights the importance of efficiency in robotic systems. Many companies however still struggle with fully utilizing their robotic welding cells. Common issues include inadequate programming and poor workflow design. Such problems often lead to downtime and operational delays.

Investing time to analyze and refine welding processes is essential. Tracking performance metrics can reveal hidden inefficiencies within the cells. Companies may find that small adjustments can lead to significant improvements. The pursuit of optimization is not just beneficial; it is necessary in today's fast-paced manufacturing environments. Embracing this challenge could set a business apart in a crowded market.

Understanding the Basics of Robotic Welding Cells

Robotic welding cells are essential in modern manufacturing. They enhance productivity and ensure consistent results. A typical welding cell contains a robotic arm, a welding machine, and safety features. Understanding how these components work together is key to maximizing efficiency.

Here are some tips to optimize your welding cells. Ensure that the robotic arm is correctly programmed for various tasks. Misprogramming can lead to wasted time. Regularly check the equipment for wear and tear. A worn part can disrupt operations. Schedule maintenance to avoid unexpected downtime.

Another factor is the layout of the cell. An efficient layout reduces the distance the robot needs to move. It minimizes cycle time. Consider the workspace's organization. Clutter can slow down operations. It's vital for the environment to be organized.

Lastly, training of your operators is crucial. A well-trained team can troubleshoot and fix minor issues quickly. Invest time in understanding how to use the equipment effectively. Continuous improvement is necessary. Each operation can always be fine-tuned.

How to Optimize Robotic Welding Cells for Maximum Efficiency?

| Aspect | Details | Recommended Value |

|---|---|---|

| Cycle Time | Duration for completing one welding cycle | < 30 seconds |

| Downtime | Amount of time the robot is non-operational | < 5% |

| Welding Speed | Speed at which welding is performed | 300 mm/min - 500 mm/min |

| Material Utilization | Amount of material used in the welding process | > 90% |

| Robot Accuracy | Precision of robot's welding position | ± 0.1 mm |

| Training Time | Time needed to train operators | < 2 weeks |

Identifying Key Factors Affecting Efficiency in Welding Operations

Robotic welding cells have become essential in modern manufacturing.

Optimizing these systems boosts productivity and reduces costs.

However, several factors affect efficiency in welding operations.

One key factor is the setup time.

Studies show that reducing setup time by 30% can lead to a 20% increase in overall efficiency.

Streamlining the programming of robotic arms minimizes downtime.

Regular maintenance is crucial as well.

Neglecting maintenance can lead to equipment failure, causing delays and increased costs.

Tips:

Invest in training for operators.

When workers understand the technology, they can troubleshoot issues quickly.

Review welding parameters frequently.

Fine-tuning settings can drastically improve quality and reduce waste.

Another important aspect is the choice of welding techniques.

Depending on the materials, some techniques may yield better results.

A detailed analysis of weld quality is recommended.

Poor quality can lead to rework, which is costly and time-consuming.

Finding the right balance between speed and quality is vital.

Tips:

Implement real-time monitoring systems.

Such systems help identify inefficiencies before they escalate.

Stay updated on industry trends.

Technologies are evolving, and adapting can provide a competitive edge.

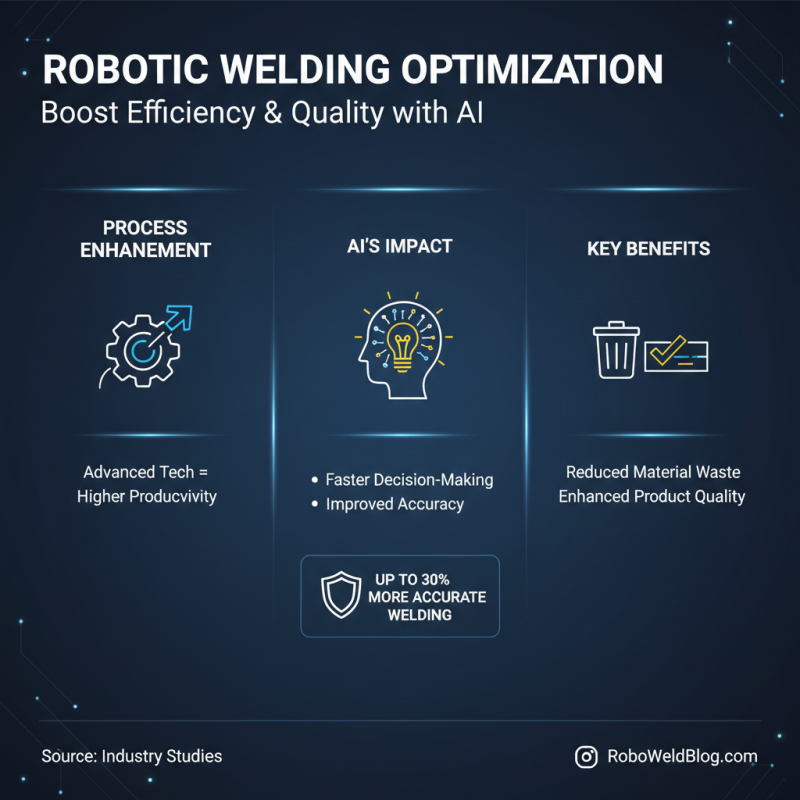

Implementing Advanced Technologies for Process Optimization

In the world of robotic welding, process optimization is key to enhancing efficiency. Implementing advanced technologies can greatly impact productivity. For example, utilizing artificial intelligence can lead to faster decision-making. Studies show that AI integration can improve welding accuracy by up to 30%. This improvement reduces material waste and enhances the quality of the final product.

Tip: Regularly update your software. Outdated systems can slow down your production line. Staying current with technology enables you to adopt the latest advancements.

Another vital factor is data analysis. Collecting and analyzing production data can reveal inefficiencies. In fact, research indicates that 70% of companies that analyze their data see significant improvements in operation efficiency. However, many manufacturers struggle with data overload. Making sense of large volumes of information can be daunting.

Tip: Focus on key metrics. Track only essential data points. This approach simplifies analysis and helps pinpoint problem areas effectively.

Remember, the quest for efficiency never ends. Embrace feedback and seek ways to improve your robotic welding cells continuously. Exploring new technologies seems vital but can also lead to over-complication. Balancing advancement with simplicity is crucial.

Streamlining Workflows to Enhance Robotics Performance

Streamlining workflows in robotic welding cells is crucial for enhancing performance. Efficient design and layout can minimize unnecessary movements. A clear path for robots helps reduce cycle times. Removing obstacles allows for quicker access to work areas. Implementing lean principles can also cut down on waste.

Tip: Use a simulation software. It helps visualize workflows before making changes. This can highlight bottlenecks and inefficiencies. Adjusting layouts based on this data can lead to significant gains in speed and productivity. Consider operator ergonomics. Workers should have easy access to tools and materials.

Even small adjustments can yield big results. For instance, placing frequently used tools within reach saves precious seconds. Training staff on best practices is essential too. They need to be aware of how to operate equipment effectively. Regular feedback can reveal areas in need of improvement.

Optimizing Robotic Welding Cell Efficiency

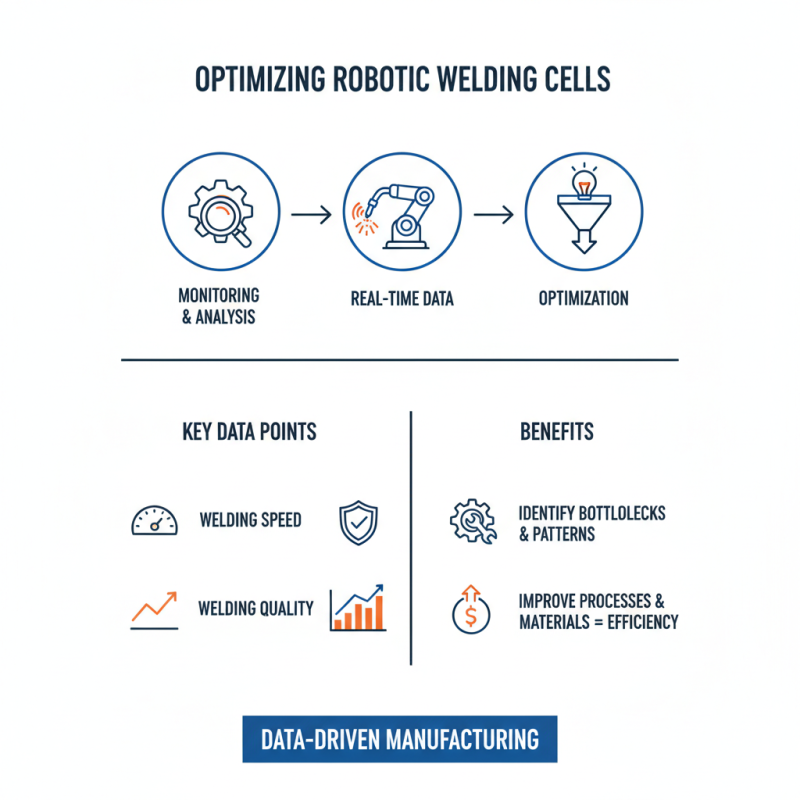

Monitoring and Analyzing Data for Continuous Improvement

Monitoring and analyzing data is crucial for optimizing robotic welding cells. By collecting real-time data, manufacturers can identify patterns and bottlenecks. For instance, tracking welding speed and quality allows operators to spot inefficiencies. This data can reveal if certain processes need adjustment or if materials require improvement.

However, data analysis is not foolproof. Sometimes, the data can be misleading. For example, high output rates might mask underlying quality issues. A thorough review is essential to distinguish between efficient production and superficial metrics. Regular audits of both data and processes can help avoid this pitfall.

Implementing feedback loops can also enhance performance. Operators should share insights from their observations. Continuous dialogue fosters a culture of improvement. Small adjustments in settings or maintenance schedules can lead to significant gains. Embracing both data and human experience ensures a balanced approach to optimization.

Related Posts

-

How to Master Robotic Spot Welding: Techniques and Best Practices

-

Top Robotic Welding Systems Trends to Watch in 2025

-

Revolutionize Your Manufacturing Process with the Latest FANUC Welding Robot Innovations

-

How to Optimize Robotic Welding Processes for Maximum Efficiency and Quality

-

Top 10 Benefits of Robotic Spot Welding in Modern Manufacturing

-

How to Choose the Right Robotic Welding Cells for Your Manufacturing Needs